Since our inception, safety has been an integral part of T&S's core values. From the production of our very first ceramic ferrule to the billions of fiber optic connections we enable in global networks today, our unwavering commitment to safety has shaped every aspect of our industrial practices. It is a principle that drives our decisions, strengthens our operational resilience, and supports the well-being of every person connected to our business — from employees to contractors, partners, and customers.

As one of the world's largest and most trusted manufacturers of fiber optic connectors and ceramic ferrules, T&S operates at the heart of the global digital infrastructure. Our products power high-speed communication networks, support data centers, and enable next-generation telecom and cloud services. But behind this technological progress lies a deeper responsibility: to prioritize safety in every process, product, and partnership. This is our story of how safety has become a cornerstone of our success and how it continues to guide us toward a safer, more responsible future.

1. A Culture of Safety from Day One

Safety is not an afterthought at T&S; it is a foundational principle that has been with us from the very beginning. When we produced our first ceramic ferrule, we knew that the precision and performance of this small but critical component would depend on the safety and control of every step of the manufacturing process.

The manufacturing of ceramic ferrules requires extreme precision and meticulous attention to detail. From material selection and molding to sintering and finishing, every stage demands a high level of accuracy and risk control. Early on, T&S adopted stringent safety protocols to protect not only our employees from occupational hazards but also the quality and reliability of our products.

This mindset extends beyond our factory floors. Safety by design is a principle that defines how we design, test, and deliver our products. Our product development process incorporates safety considerations at every stage.

"When safety is prioritized from the start, quality naturally follows," says Mr. Geng, T&S's Production Manager. "We want our products to be safe for our workers to produce, safe for our customers to use, and safe for the environment."

2. Safety in Our Manufacturing Process

The production process for ceramic ferrules and fiber optic connectors involves sophisticated machinery, high-temperature equipment, and fine-tuned precision. Managing the inherent risks in this environment requires a robust system of controls, which is why T&S has implemented a comprehensive Safety Management System (SMS) at every facility.

2.1. Key Elements of Our Manufacturing Safety Strategy:

Automated Precision Equipment: Automation reduces human interaction with hazardous processes, such as high-temperature sintering, grinding, and polishing. By using advanced robotics and AI-controlled machines, T&S minimizes the risk of heat exposure, cuts, and repetitive strain injuries.

Protective Gear and Personal Safety Equipment (PPE): Employees are equipped with cutting-edge PPE, such as anti-cut gloves, safety goggles, and hearing protection.

Real-Time Monitoring: We use IoT-enabled safety sensors and AI-powered data analytics to monitor temperature, humidity, and air quality on production floors. Real-time alerts enable immediate action if conditions deviate from acceptable safety thresholds.

Comprehensive Safety Training: Every T&S employee receives mandatory safety training, which is regularly updated to reflect new technologies, processes, and potential risks. Our goal is to build a workforce that is as skilled in safety as it is in production.

Through a combination of human oversight, technological innovation, and rigorous operational controls, T&S ensures that every employee can work in a safe and secure environment.

3. Our Commitment to Employee Safety and Well-being

For T&S, safety is not limited to preventing accidents — it extends to the well-being of every employee. We view our workforce as a vital part of our global success, and their physical and mental health is a top priority.

3.1. Our Employee Safety and Well-being Initiatives Include:

24/7 Health Support: We offer on-site health consultations, access to mental health counselors, and health and wellness programs tailored to reduce stress and anxiety.

Ergonomics Assessments: T&S conducts routine ergonomic assessments to ensure employees have access to equipment and workstations that minimize physical strain. This is especially crucial for operators working on fiber optic assembly lines.

Zero-Incident Mentality: Our philosophy of "zero incidents" isn't just about accident prevention — it's about fostering a mindset where employees actively look out for one another. By encouraging peer-to-peer safety coaching, we create an environment where employees feel empowered to raise concerns and suggest improvements.

Our approach to employee well-being has earned T&S recognition from industry associations and global clients. Our safety programs have become benchmarks for excellence in optical component manufacturing.

4. Product Safety and Customer Assurance

The safety of our products is another fundamental aspect of our responsibility. Fiber optic networks are critical infrastructure, and any failure in a component could result in network downtime, financial loss, or compromised data security. That is why T&S designs its products with built-in safety and reliability features.

4.1. How We Ensure Product Safety:

Compliance with Global Standards: All T&S products comply with industry standards like IEC, Telcordia, and RoHS regulations, ensuring environmental safety, material safety, and technical performance.

Stringent Quality Control: Each batch of ceramic ferrules and fiber optic connectors undergoes multiple inspection stages, from visual inspections to automated optical testing.

Environmental Safety: Our products are designed with environmental responsibility in mind. We prioritize lead-free materials and use environmentally friendly manufacturing processes.

By prioritizing product safety, T&S not only protects our customers from disruptions but also builds trust as a reliable, world-class supplier.

5. Building Safer Communities

Our commitment to safety extends beyond our company to the local communities where we operate. As a multinational enterprise, we engage with stakeholders, governments, and NGOs to promote responsible manufacturing practices.

5.1. How T&S Supports Community Safety:

Local Hiring and Skills Training: T&S partners with technical schools and universities to provide hands-on training and offer employment opportunities in local communities.

Environmental Responsibility: We maintain sustainable waste management practices and control emissions from our production processes, ensuring cleaner air and water for neighboring communities.

Emergency Preparedness: T&S works with community leaders to develop emergency response plans for potential incidents, such as fires or natural disasters.

By fostering safe communities, we ensure that our business thrives alongside the communities that support us.

6. The Future of Safety at T&S

As the demands of the optical communications industry grow, so do our commitments to safety. New technologies like AI, automation, and machine learning offer new opportunities to advance workplace safety. By integrating these innovations, we plan to:

Further reduce human exposure to high-risk tasks.

Leverage predictive analytics to anticipate safety risks.

Continue our zero-incident approach to ensure every employee returns home safely.

Conclusion: Safety Defines Us

At T&S, safety is not just a goal — it's a commitment we make every day. It is a driving force behind our engineering precision, operational excellence, and global reputation. From our first ceramic ferrule to the billions of fiber optic connections we support today, safety has always been our guiding principle.

This commitment to safety allows us to create a workplace where employees thrive, a production system that guarantees quality, and a global supply chain that our customers can trust. As we continue to lead in the world of fiber optic interconnection technology, we will remain dedicated to ensuring the safety of our people, our products, and the communities we serve.

Because at T&S, safety is at our core — and it always will be.

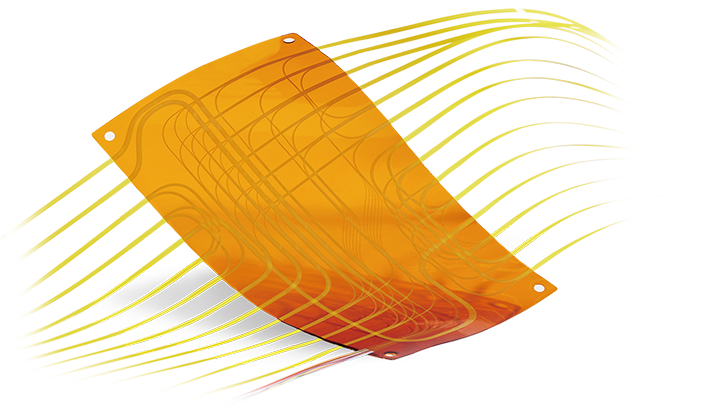

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm.

MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm. MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design.

MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design. EN

EN

jp

jp  fr

fr  es

es  it

it  ru

ru  pt

pt  ar

ar  el

el  nl

nl