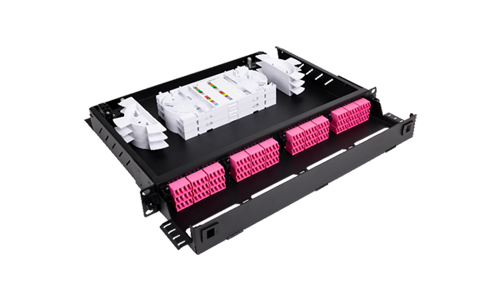

Fiber Optic Patch & Splice Enclosures are called many different names due to respective habits across the industry: Fiber Enclosures, Termination Panels, Patch & Splice Panels, Fiber Splice Box, Splice Distribution, Fiber Splice Panel, Patch Panel, Fiber Optic Panel, Patch & Splice Panel, Patch & Splice Module, Fiber Splice Closure, Fiber Splice Chassis and the like. No matter what you call them, they all describe a box-like object that contains devices to connect various fiber optic cables.

Fiber Optical Enclosures come in different variation such as rack-mount, wall-mount and indoor or outdoor.

The rack mount type is made for 19-inch rack mounting. They can be one or more rack units (RU) depending on the number of connections and patch density required for your applications.

One type is designed with fixed front panels for mounting adapters. Another incorporates removable front panels which can accommodate simplex, duplex or quad adapter panels, with which, capacity adjustment and expansion can be carried out easily.

The rack mount enclosures come in two basic versions. One is the slide-out variety, and the other incorporates a removable top cover (fixed variety). The slide-out type is usually more expensive while the fixed type is less expensive but requires the user to remove the whole enclosure from the rack to gain internal cabling access when both the two has similar or adjacent physical configurations.

The indoor wall-mount enclosures can be widely seen in many constructions, while outdoor enclosures are generally used on pedestal or power pole scenario.

Another frequently seen component is the splice tray. It’s used for efficient management and storage of the spliced fiber optic cables.

Fiber Optic Adapters are installed onto the slots in the enclosure to help mating various connectors. Fiber optic pigtails (a fiber optic cable with a connector on one end), mate with the adapters and the fusion-spliced end are stored and protected in the splice tray.

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing MDC Solution

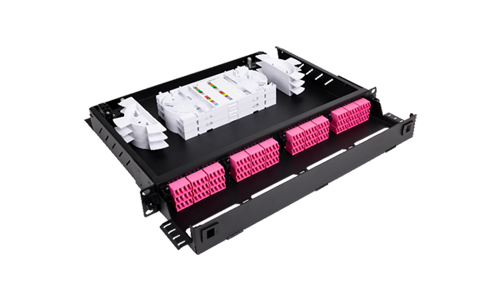

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm.

MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm. MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design.

MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design. EN

EN

jp

jp  fr

fr  es

es  it

it  ru

ru  pt

pt  ar

ar  el

el  nl

nl

_and_High-Reflection_(HR)_Optical_Coatings.webp)