In the coming future, fiber optical sensing is playing an increasingly important role and taking a bigger share in Internet of Things, based on which smart city, smart traffic, smart medical treatment, smart home and the like may gradually be constructed, while FBG sensing is definitely an indispensable participant. T&S is Fiber Optical Sensing Engineering R&D Center of Guangdong Province, which focuses on the development of FBG sensing and its application. T&S now has dozens of successful exclusive cases both domestic and overseas especially in smart grid, oil and gas IoT and rail-traffic systems.

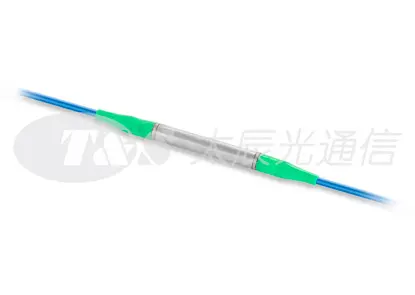

FBG Temperature Sensor

The reflection wavelength of the FBG (Bragg wavelength) depends on the grating characteristics (period, modulation) and is influenced by ambient conditions such as strain and temperature. In the case of temperature sensing the Bragg wavelength is a function of the temperature. This temperature dependence results from changes of the refractive index of the fiber as well as from thermal expansion of the glass material.

FBG Pressure Sensor

Fiber bragg grating sensors are well suited for pressure measurements in different challenging environments in the medical market, process industry or the oil and gas sector. They offer many advantages like electromagnetic immunity, small size, mechanical robustness and non-inflammability due to the used glass. Furthermore, FBG sensors offer the possibility for multiplexed pressure measurement for example along with medical catheters or in boreholes for oil and gas exploration.

FBG Strain Sensor

Fiber Bragg Gratings are known to have a stable and reliable wavelength response as a function of the applied strain. FBGs are therefore winning increasing attention in the field of strain measurements.

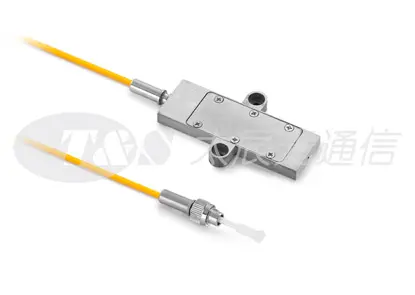

FBG Displacement Sensor

T&S displacement sensor is a ruggedized Fiber Bragg Grating (FBG) sensor designed to measure linear displacement on different types of structures. The sensor uses two FBGs for effective temperature compensation. It can be used in a large range of monitoring applications, like sustaining walls, bridge piles or buildings.

FBG Vibration Sensor

T&S FBG vibration sensor is a high-precision vibration sensor tailored to measure acceleration at different frequencies from 0 to 50Hz.

The FBG vibration sensor can be used in a large range of monitoring applications where low frequency, but relevant amplitude vibrations are present, including measuring load-induced vibration of civil structures and ambient cable vibrations.

Select your optical interrogators

T&S offers a complete product portfolio for your sensing application: from the sensors (strain, pressure, temperature, vibration and displacement) to optical interrogators to monitoring solutions.

中文

中文 EN

EN

jp

jp  fr

fr  es

es  it

it  ru

ru  pt

pt  ar

ar  el

el  nl

nl

Call us on:

Call us on:  Email Us:

Email Us:  8 Jinxiu Middle Road,

8 Jinxiu Middle Road,