Optical thin-film coatings play a critical role in controlling how light interacts with optical components. Among the most widely used are anti-reflection (AR) coatings, which minimize surface reflections and enhance transmission, and high-reflection (HR) coatings, which maximize reflectivity for mirrors and laser optics. These coatings are indispensable in applications such as fiber optics, imaging systems, laser processing, sensors, and photonics research.

1. Anti-Reflection (AR) Coatings

1.1 What Is an Anti-Reflection Coating?

An anti-reflection (AR) coating is a dielectric thin film applied to transmissive optical components—such as lenses, windows, prisms, and filters—to reduce unwanted reflections and improve transmission efficiency.

By minimizing Fresnel reflection losses, AR coatings enhance signal strength, reduce ghost images and stray light, and improve optical system performance.

These coatings are typically fabricated by physical vapor deposition (PVD). For complex or highly curved surfaces, thermal atomic layer deposition (ALD) provides a conformal coating with atomic-level thickness precision, ensuring uniform performance over the entire optical surface.

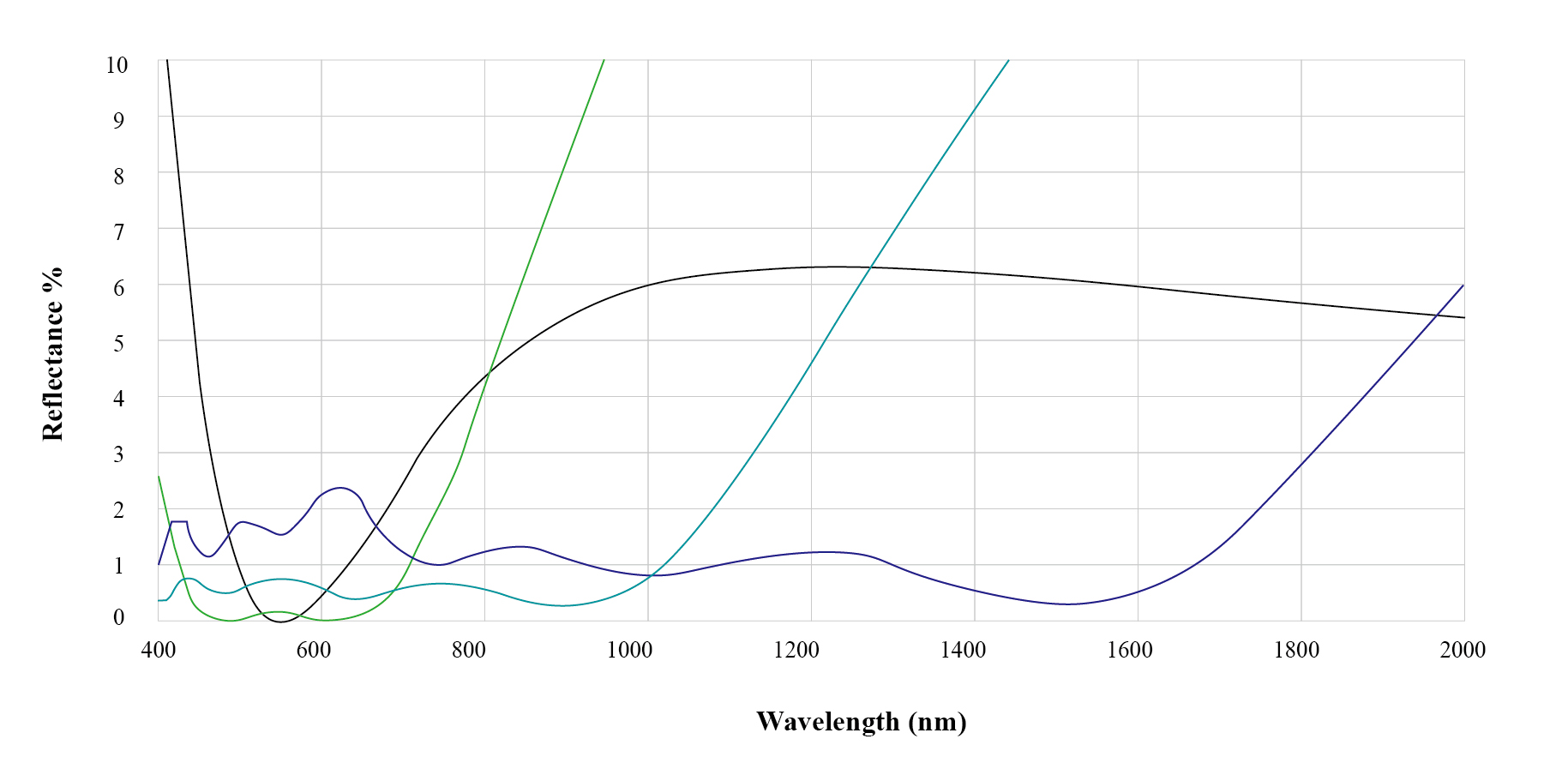

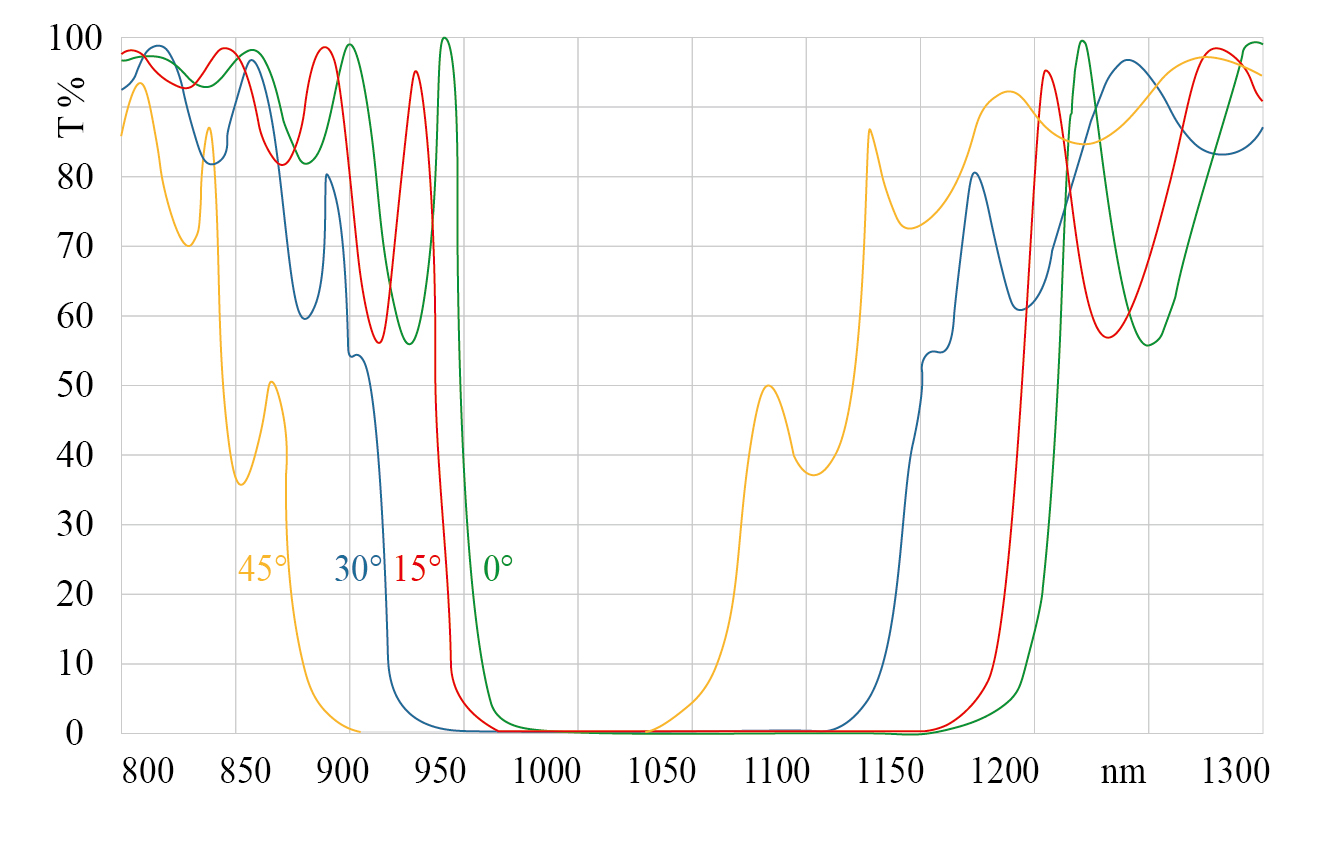

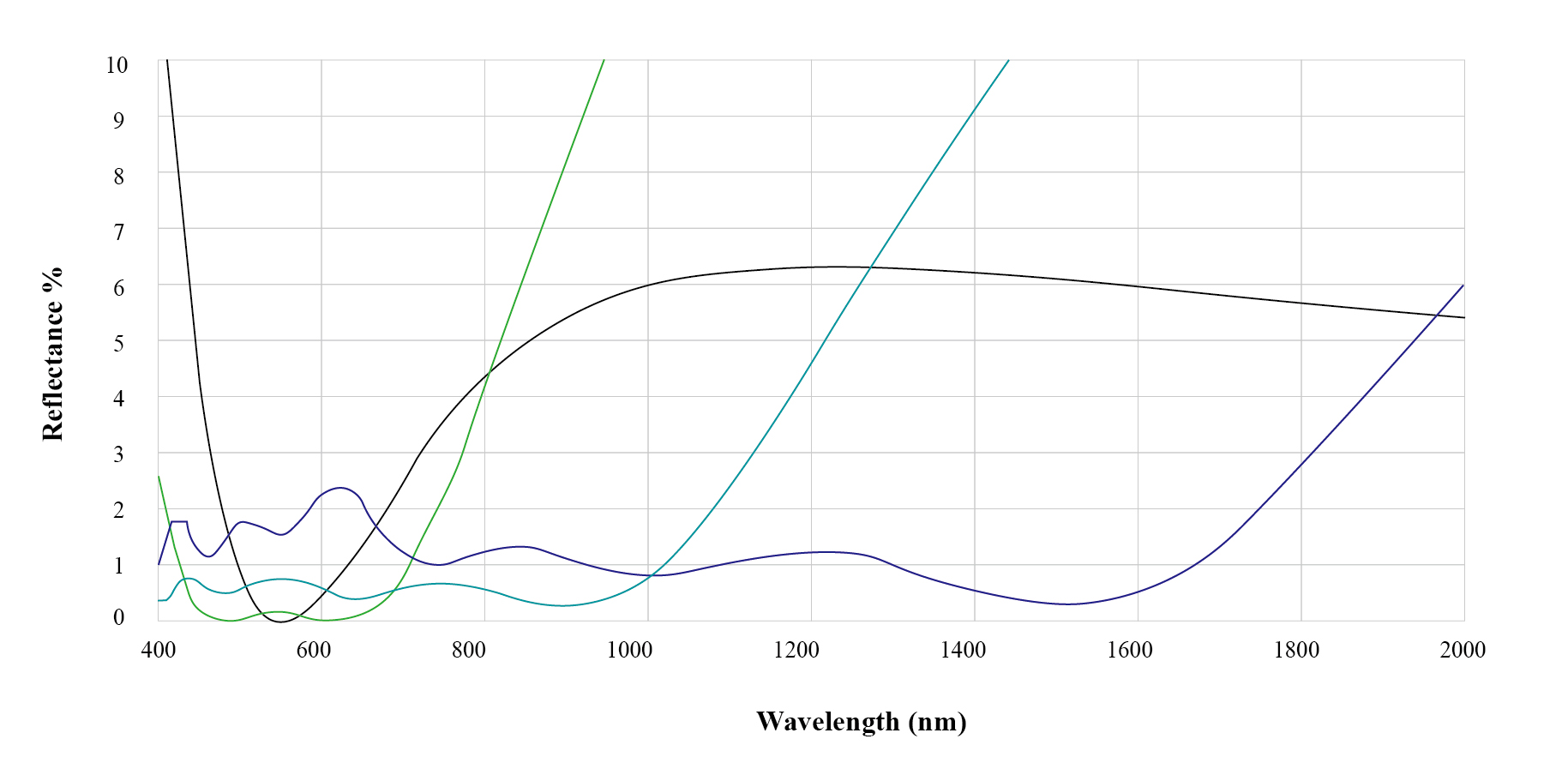

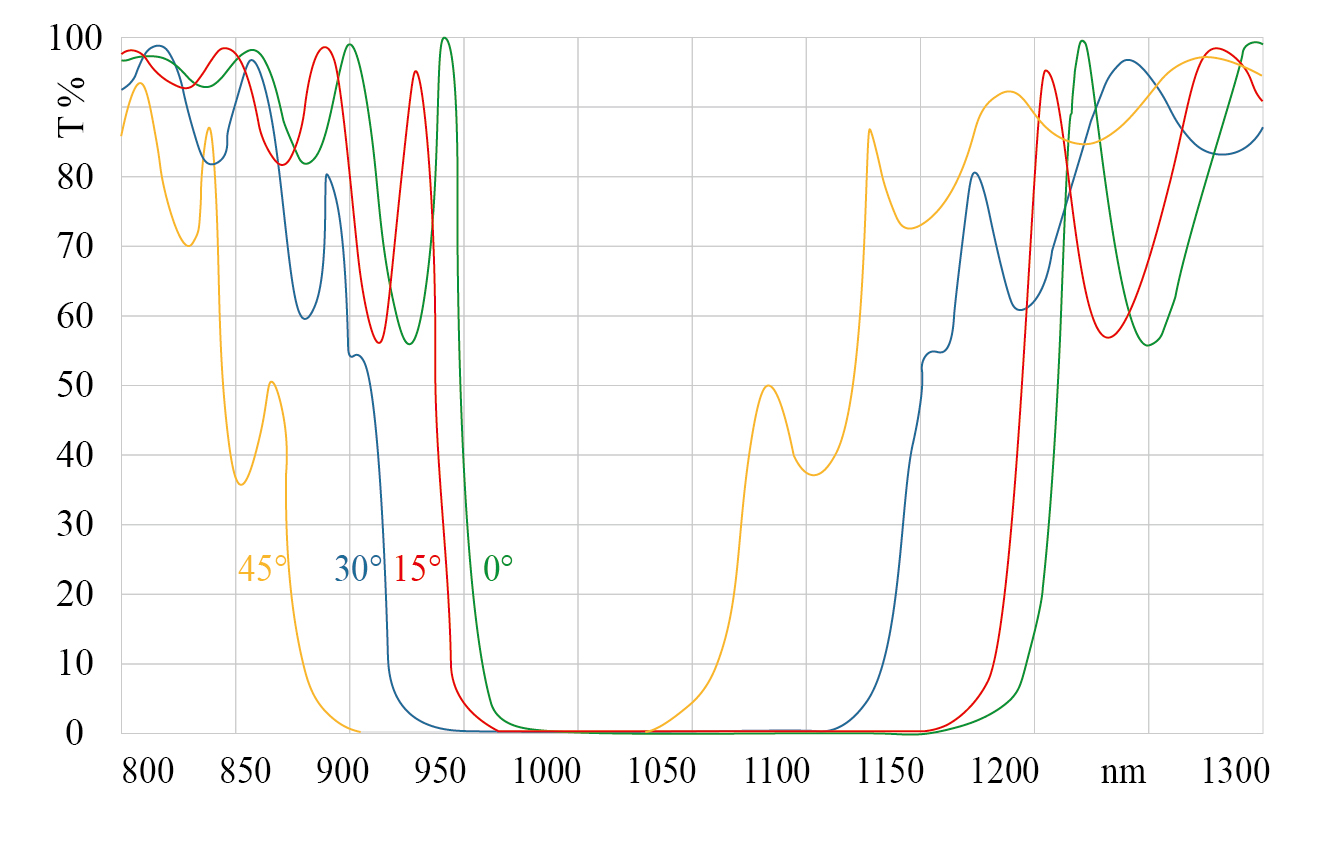

Figure 1. AR Coating Performance for various Bandwidths

1.2 How Do AR Coatings Work?

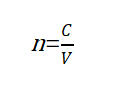

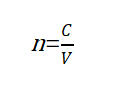

When light passes from one medium to another—such as from air to glass—part of the light is reflected and part is transmitted. The fraction of reflected light is determined by Fresnel’s equations, which depend on the refractive indices of the two materials. Each material has an index of refraction that is calculated as follows:

where c is the speed of light in a vacuum, and v is the speed of light in the medium, the material.

Fresnel's Equation defines the fraction of light that is reflected as follows:

An AR coating minimizes this reflection through destructive interference between partial reflections at two interfaces:

When the film thickness equals one-quarter of the wavelength (λ/4), the reflected waves from both interfaces are 180° out of phase, canceling each other out and greatly reducing reflected intensity.

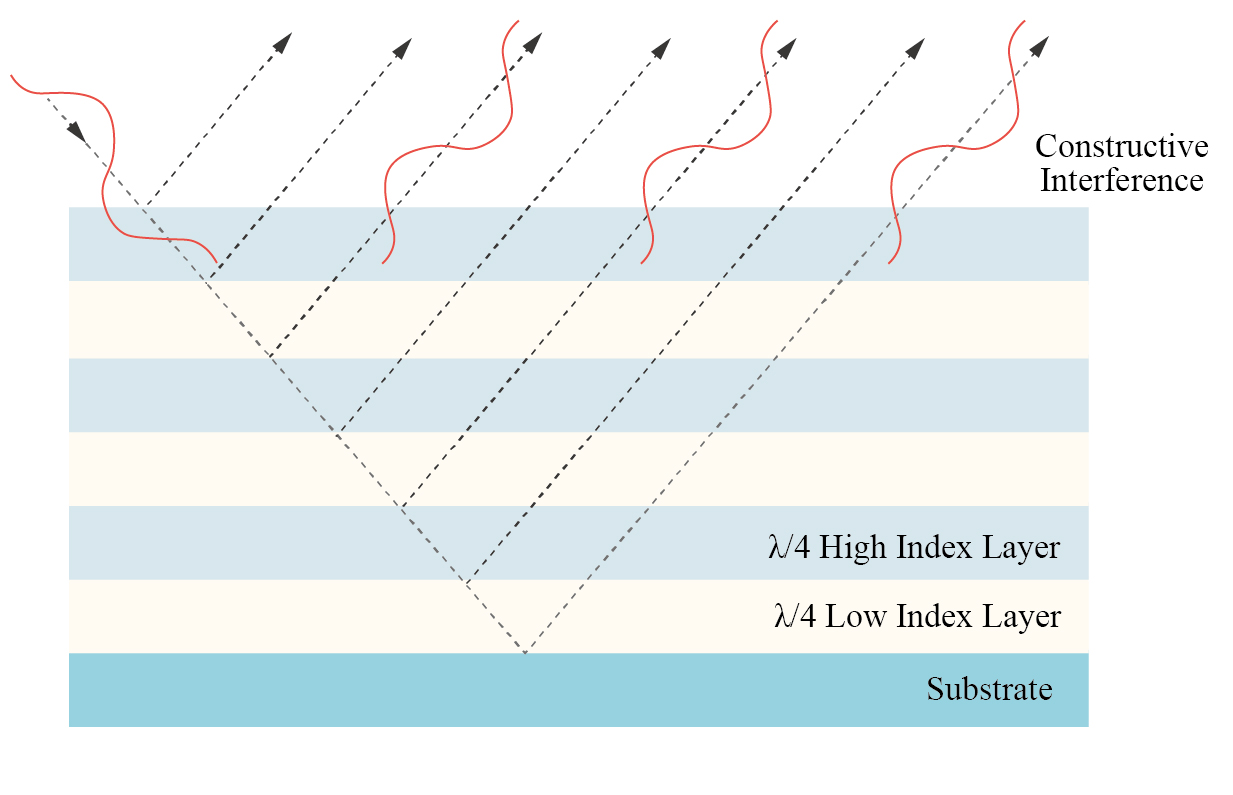

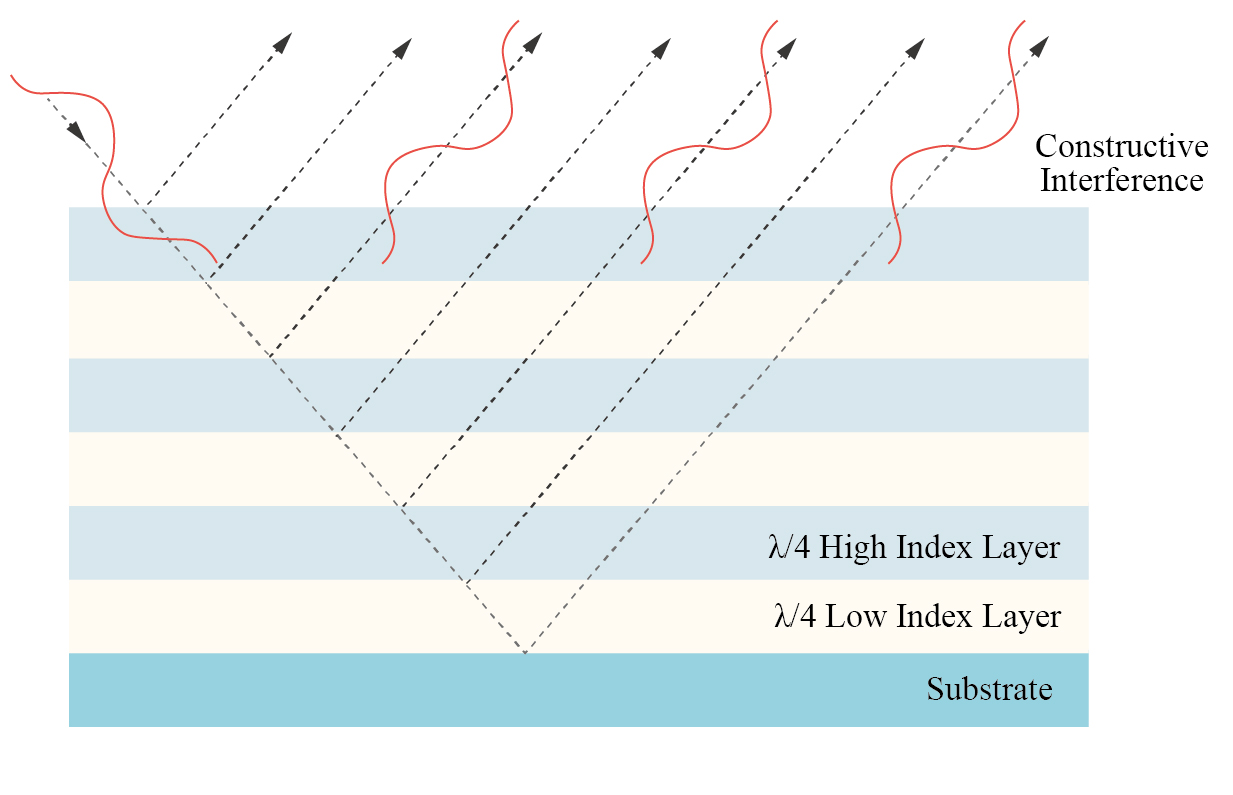

Figure 2.Anti-Reflection (AR) Coating

An example of how a quarter-wave coating works. The reflected light from each of the surfaces (R1 & R2) are 180 degrees out of phase, resulting in destructive interference.

Because this interference effect depends on wavelength and angle, multilayer AR coatings are designed to provide broadband and wide-angle performance.

1.3 Design Considerations for AR Coatings

Wavelength Range and Angle of Incidence:

AR coatings are optimized for a specific spectral range and angle. Using them outside the design range reduces efficiency.

Surface Application:

Both entry and exit surfaces are usually AR-coated to maximize transmission.

Optical System Type:

Broadband imaging systems typically use multilayer broadband AR coatings (BBAR), while single-wavelength laser systems use V-type coatings.

Laser Stability:

Back reflections can destabilize laser cavities and damage sensitive components, making high-performance AR coatings essential.

Infrared and Specialty Systems:

For SWIR (short-wave infrared) or NIR imaging, coatings must be specifically designed to minimize IR reflections and maximize signal-to-noise ratio.

1.4 Measuring AR Coating Performance

The quality and durability of an AR coating are verified using precision optical metrology techniques, such as:

UV-Vis Spectroscopy:

Determines absolute and specular reflectance, and quantifies transmission and absorption losses.

Laser Reflectometry:

Measures reflectivity and transmission with high angular precision across a wide range of incident angles.

Cavity Ring-Down Spectroscopy (CRDS):

Ultra-sensitive detection of optical loss (absorption + scatter) at parts-per-million (ppm) levels.

Coating Stress and Figure Distortion:

Coating stress can deform optical surfaces; testing involves measuring curvature changes of coated reference wafers.

1.5 Common Types of Anti-Reflection Coatings

AR coatings are essential in a wide range of optical applications — from lenses and filters to displays and photovoltaic cells. Common types include broadband antireflective (BBAR) coatings, V-coatings, and magnesium fluoride coatings.

(1) Broadband Antireflective (BBAR) Coatings

BBAR coatings consist of multiple alternating layers of high- and low-refractive-index materials.

They provide low reflectance and high transmission over broad spectral bands and are widely used in imaging optics, laser systems, and telecommunications.

(2) V-Type Coatings

Designed for a specific laser wavelength or narrow spectral band, these multilayer coatings achieve extremely low reflectance at the design wavelength. The reflectance curve forms a characteristic “V” shape, with steep performance falloff outside the center wavelength.

(3) Magnesium Fluoride (MgF₂) Coatings

A single-layer AR coating made from low-index MgF₂ (n ≈ 1.38 at 633 nm).

MgF₂ offers excellent broadband transmission from 120 nm to 8000 nm, high durability, and a high laser damage threshold.

It is commonly used for UV and visible optics, reducing surface reflectivity from ~4% to ~1.3%.

2. High-Reflection (HR) Coatings

2.1 What Is a High-Reflection Coating?

A high-reflection (HR) coating is a dielectric or metallic thin film applied to reflective components such as mirrors, prisms, and laser cavity optics.

The purpose is to maximize surface reflectivity while minimizing absorption, transmission, and scatter losses.

While AR coatings reduce reflection, HR coatings achieve the opposite effect—constructive interference enhances reflection efficiency.

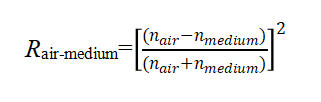

Figure 3. HR Coating Transmission vs. Wavelength at Various Angles of Incidence

2.2 Types of HR Coatings

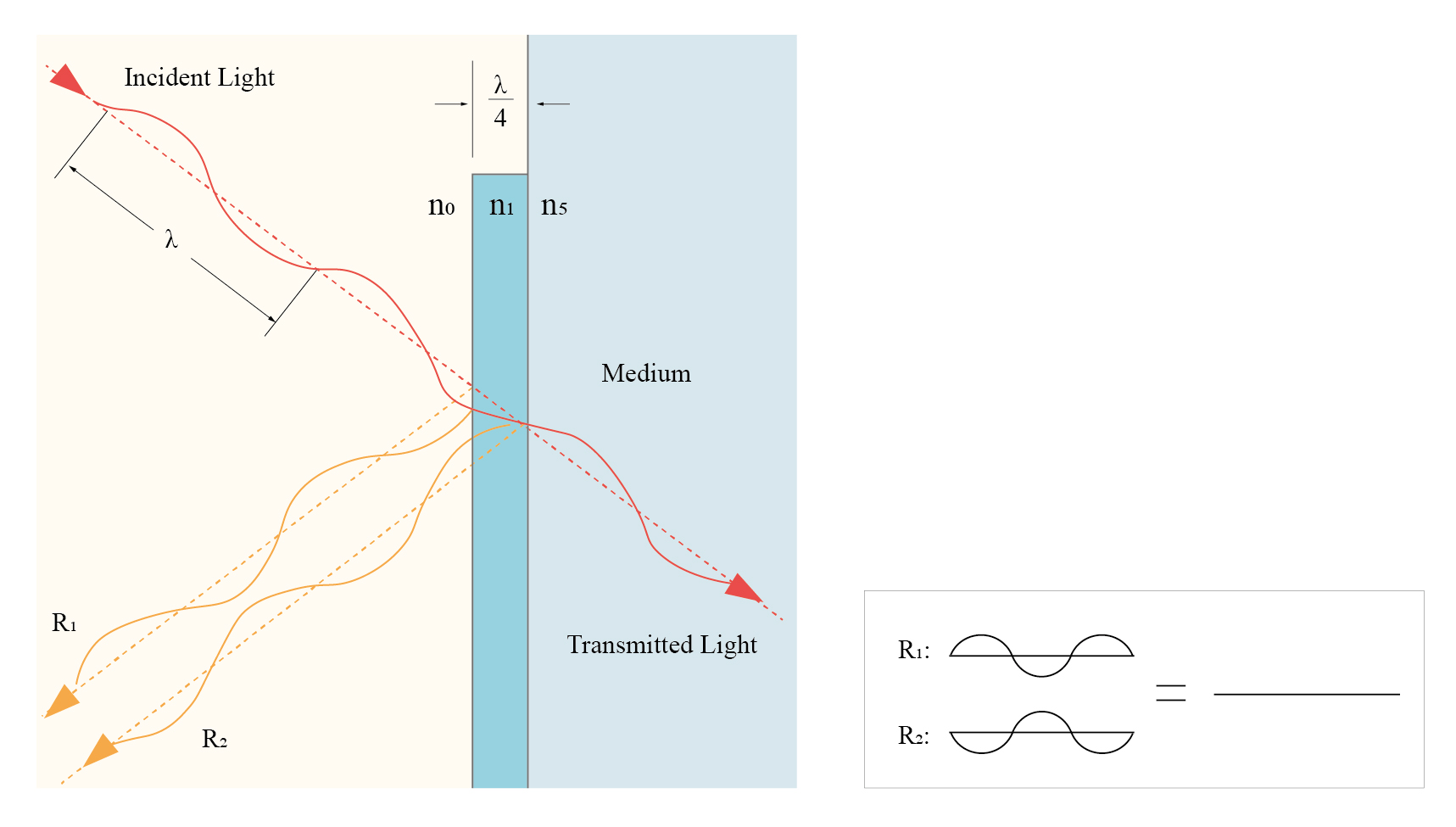

(1) Dielectric HR Coatings

Dielectric mirrors use alternating high- and low-index layers with quarter-wave optical thicknesses. These coatings achieve constructive interference, reinforcing reflected light and enabling reflectivity greater than 99.9% within their design wavelength range.

Figure 4. High-Reflection (HR) Coating

An example of how a high-reflective coating works. Reflections from the multiple interfaces interfere constructively, producing a high overall reflectance at the designed wavelength.

Advantages:

Limitations:

Narrow operational bandwidth

Sensitive to wavelength, angle of incidence, and polarization

(2) Metallic HR Coatings

Metallic coatings—such as aluminum (Al), silver (Ag), and gold (Au)—reflect light via the free-electron oscillation mechanism in metals. They provide broadband reflectivity across wide spectral and angular ranges.

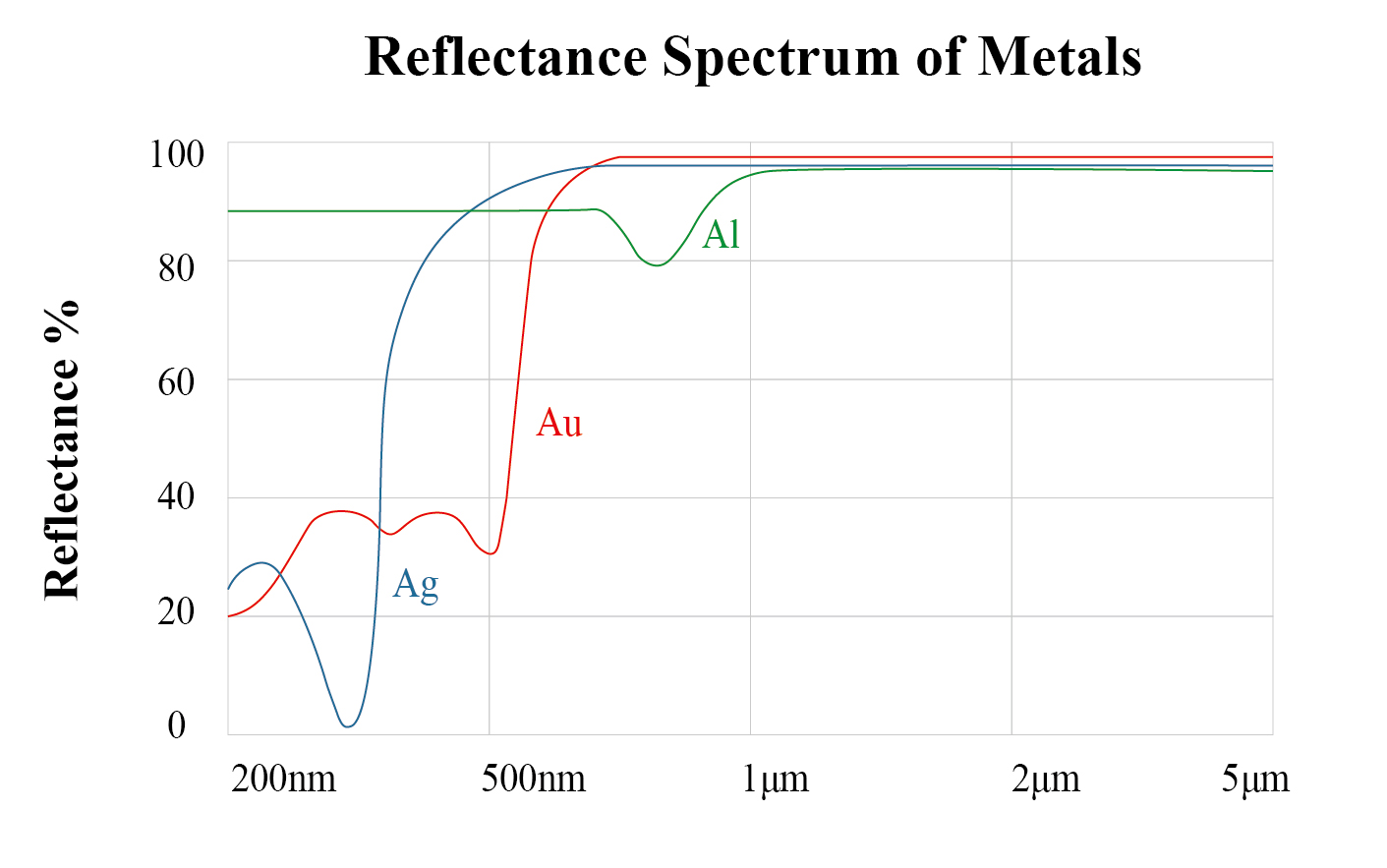

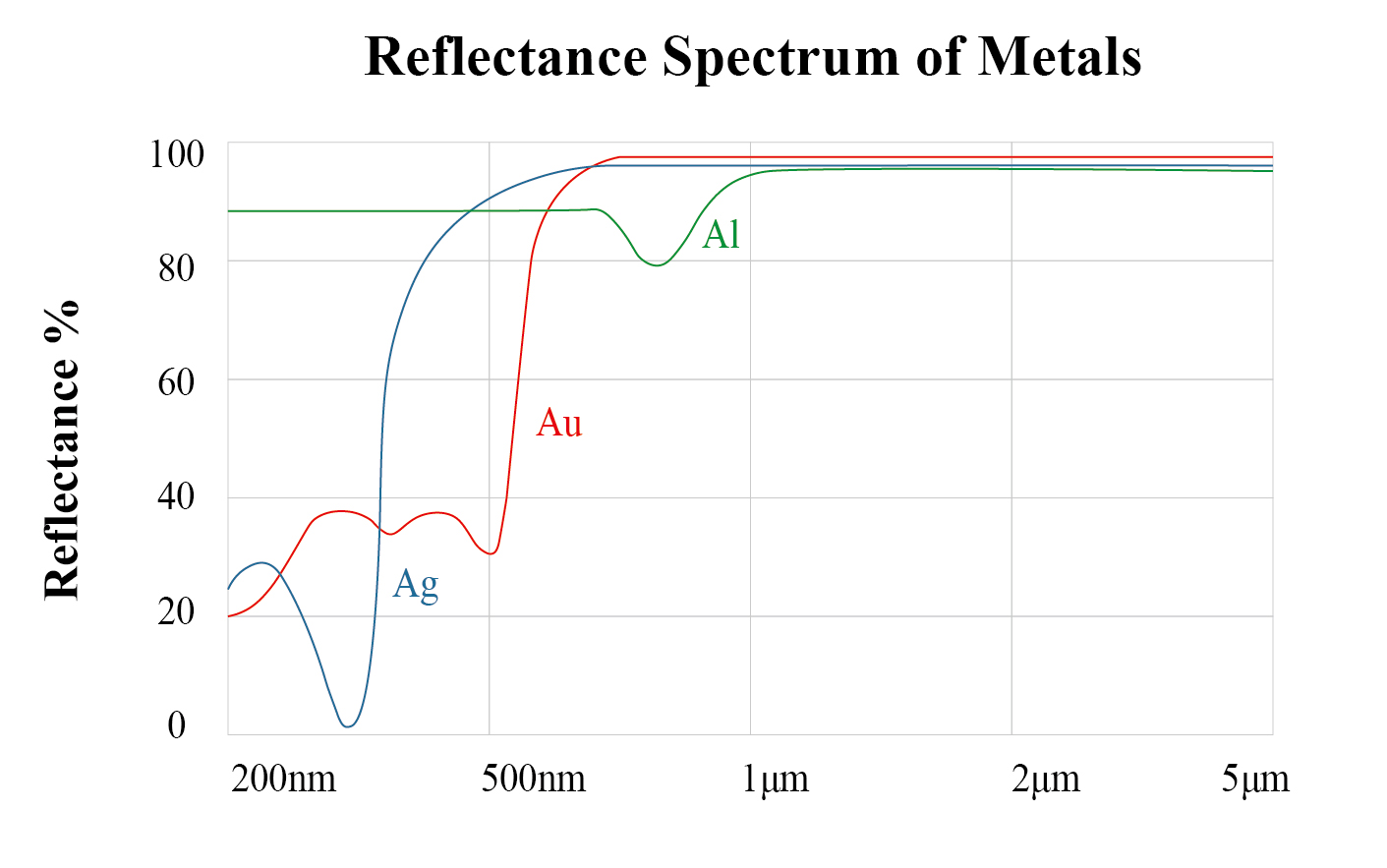

Figure 5. Reflectance Spectrum of Metals

Metal | Typical Range | Key Characteristics |

Aluminum (Al) | UV–NIR | Good broadband reflectance, durable, moderate oxidation resistance |

Silver (Ag) | Visible–IR | Highest reflectance in visible–IR, requires protection from tarnish |

Gold (Au) | NIR–IR | Excellent IR performance, poor UV/visible reflectance |

Enhanced Metallic Coatings:

Add a thin dielectric overlayer to boost reflectivity in a specific wavelength range.

Protected Metallic Coatings:

Use a hard dielectric overcoat to prevent oxidation and abrasion with minimal optical impact.

Handling Tip:

Avoid touching mirror surfaces directly. Clean only with dry air or approved solvents (e.g., isopropanol), taking care to prevent scratches.

2.3 Dielectric vs. Metallic HR Coatings

Property | Dielectric HR Coating | Metallic HR Coating |

Reflectivity | Up to >99.9% (narrowband) | 90–98% (broadband) |

Bandwidth | Narrow | Wide |

Angle Sensitivity | High | Low |

Polarization Dependence | High | Low |

Durability | Excellent | Moderate |

Laser Damage Threshold | High | Lower |

Applications | Laser mirrors, dielectric filters | Broadband mirrors, beam steering, general optics |

3. Summary

Anti-reflection (AR) and high-reflection (HR) coatings are essential for optimizing light control in modern optical and photonic systems. AR coatings minimize reflection losses and enhance transmission in lenses, filters, and fiber-optic components. HR coatings maximize reflectivity for mirrors, resonators, and laser beam-steering elements.

Selecting the right coating type—dielectric or metallic, single-layer or multilayer—depends on the required wavelength range, angle of incidence, environmental stability, and laser power handling.

Together, AR and HR coatings form the foundation of advanced optical coating technology, enabling high-precision performance in telecommunications, defense, biomedical imaging, and industrial laser systems.

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm.

MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm. MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design.

MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design. EN

EN

jp

jp  fr

fr  es

es  it

it  ru

ru  pt

pt  ar

ar  el

el  nl

nl