Is Hollow-Core or Multi-Core the Future of Fiber Technology?

The question of whether Hollow-Core Fiber (HCF) or Multi-Core Fiber (MCF) will define the future of optical communication has become one of the most talked-about topics in the industry. Both technologies represent bold departures from traditional single-core fiber and hold great promise for improving transmission speed, capacity, and efficiency. Yet despite their potential, each faces unique technical and economic hurdles that will shape how quickly they enter large-scale deployment.

While HCF is often praised for its unparalleled transmission speed, MCF is steadily emerging as the more scalable and commercially realistic technology for next-generation networks. To understand why, it’s worth exploring how these two fibers differ—and where each one truly excels.

Understanding the Two Technologies

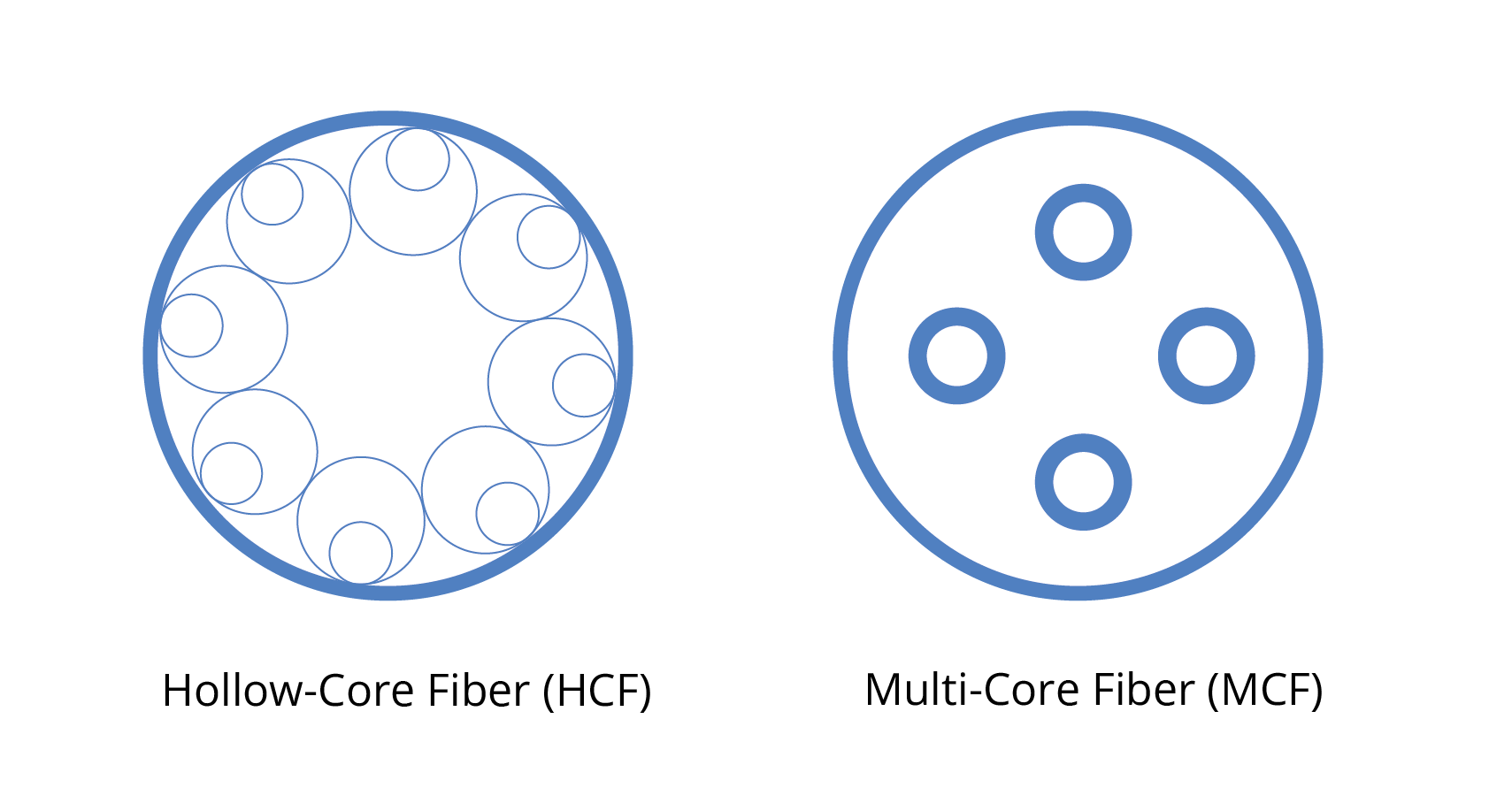

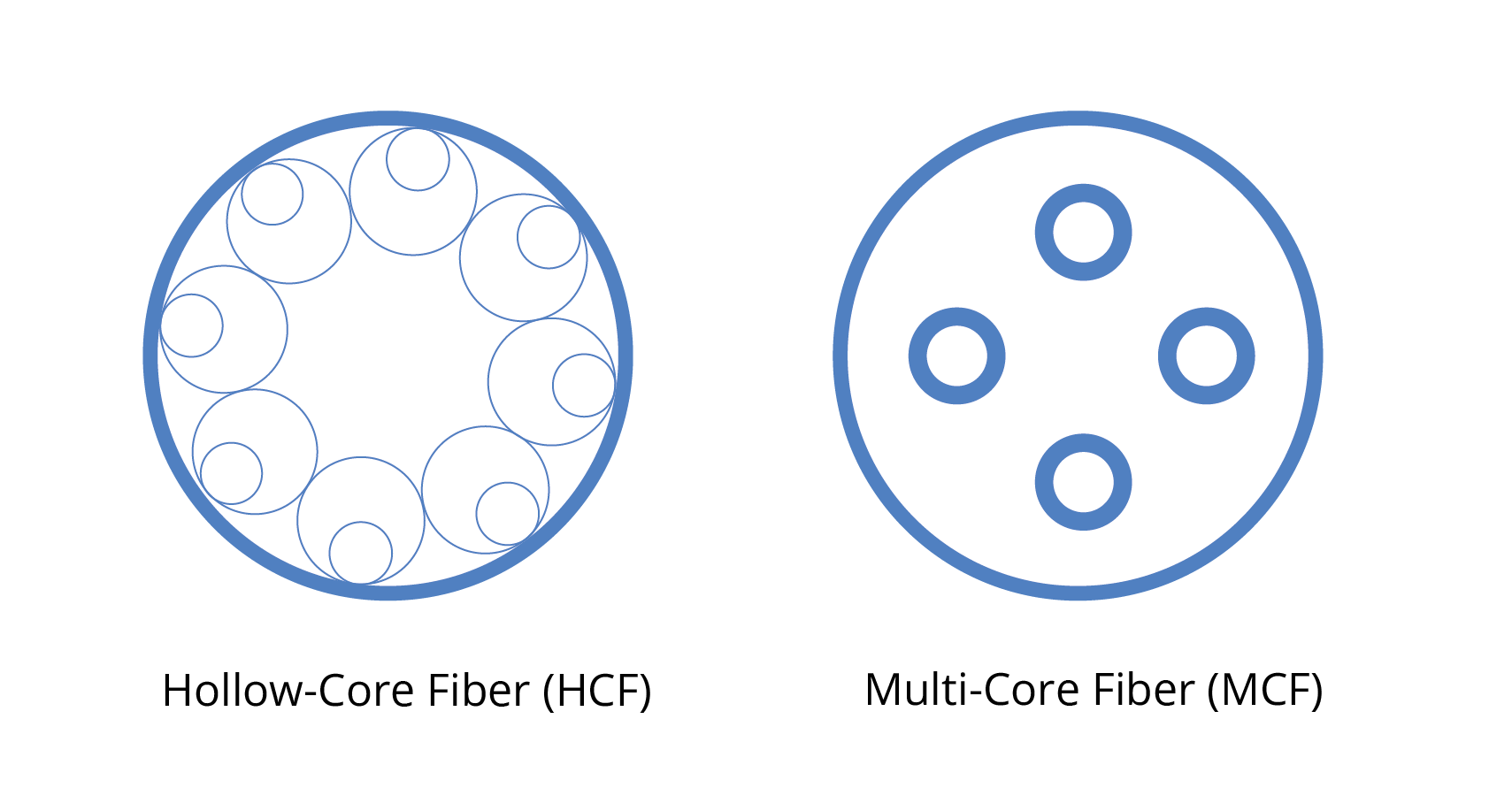

Hollow-Core Fiber (HCF) replaces the conventional glass core with a hollow, air-filled channel, allowing light to propagate through air rather than glass. This structural change minimizes scattering and material dispersion, resulting in exceptionally low latency and higher transmission velocity. Because light moves faster in air, HCF can reduce latency by as much as 30% compared with standard fiber, making it particularly valuable in environments where every microsecond counts—such as high-frequency trading and precision edge computing.

However, these benefits come at a considerable cost. HCF is difficult to fabricate, fragile to handle, and expensive to splice. Its limited compatibility with existing fiber infrastructure and the challenge of mass production with consistent performance mean that its use remains confined to niche, high-value applications.

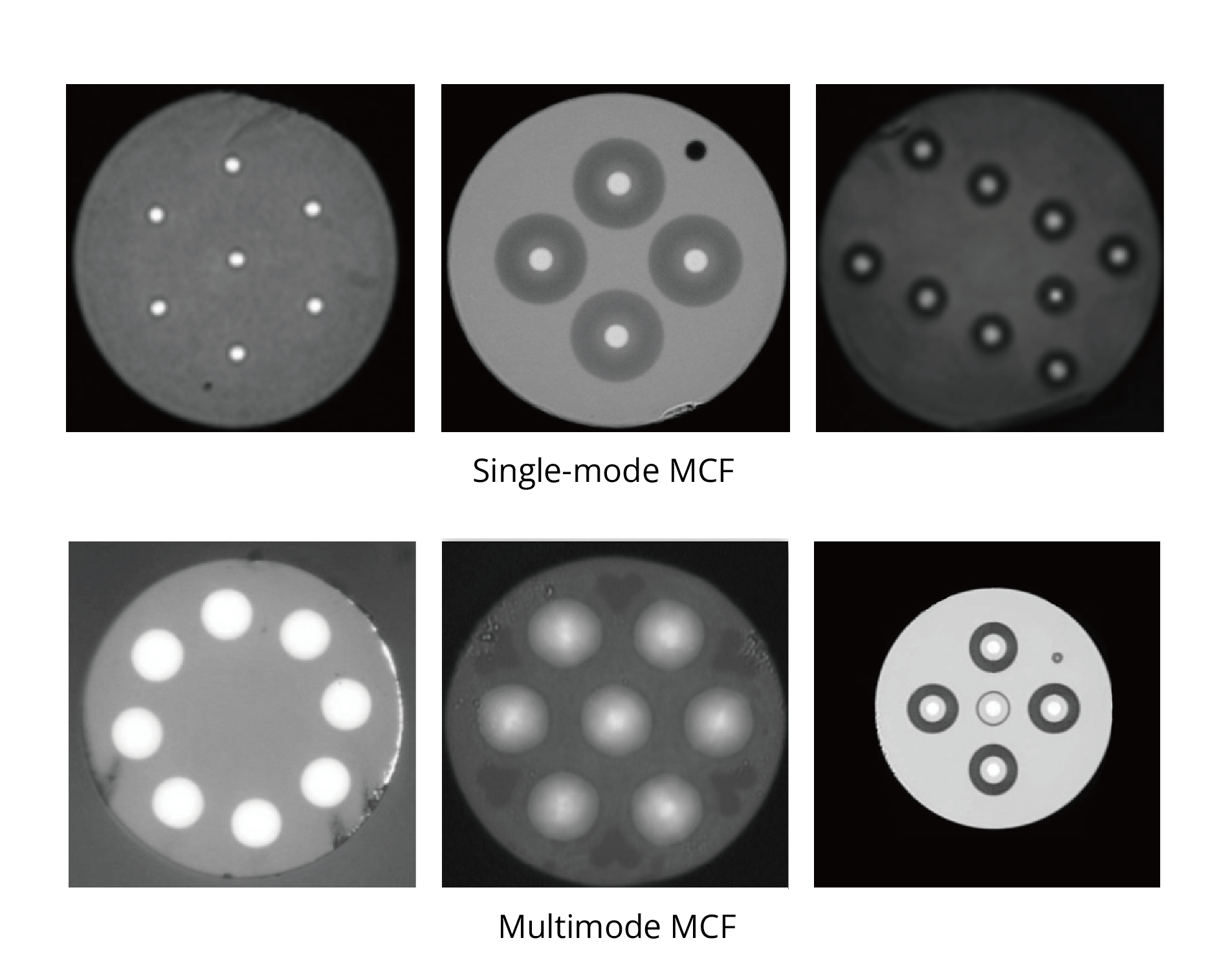

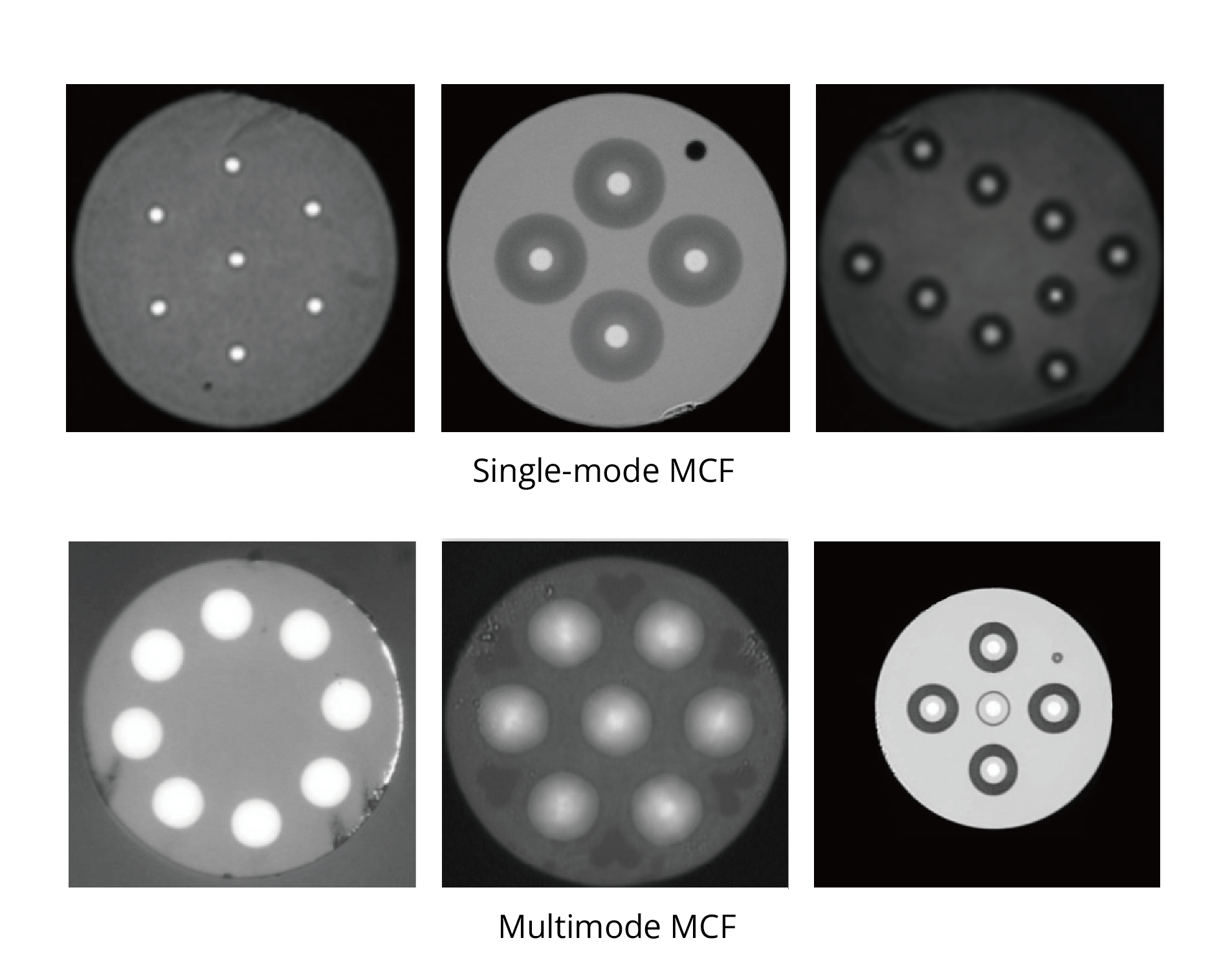

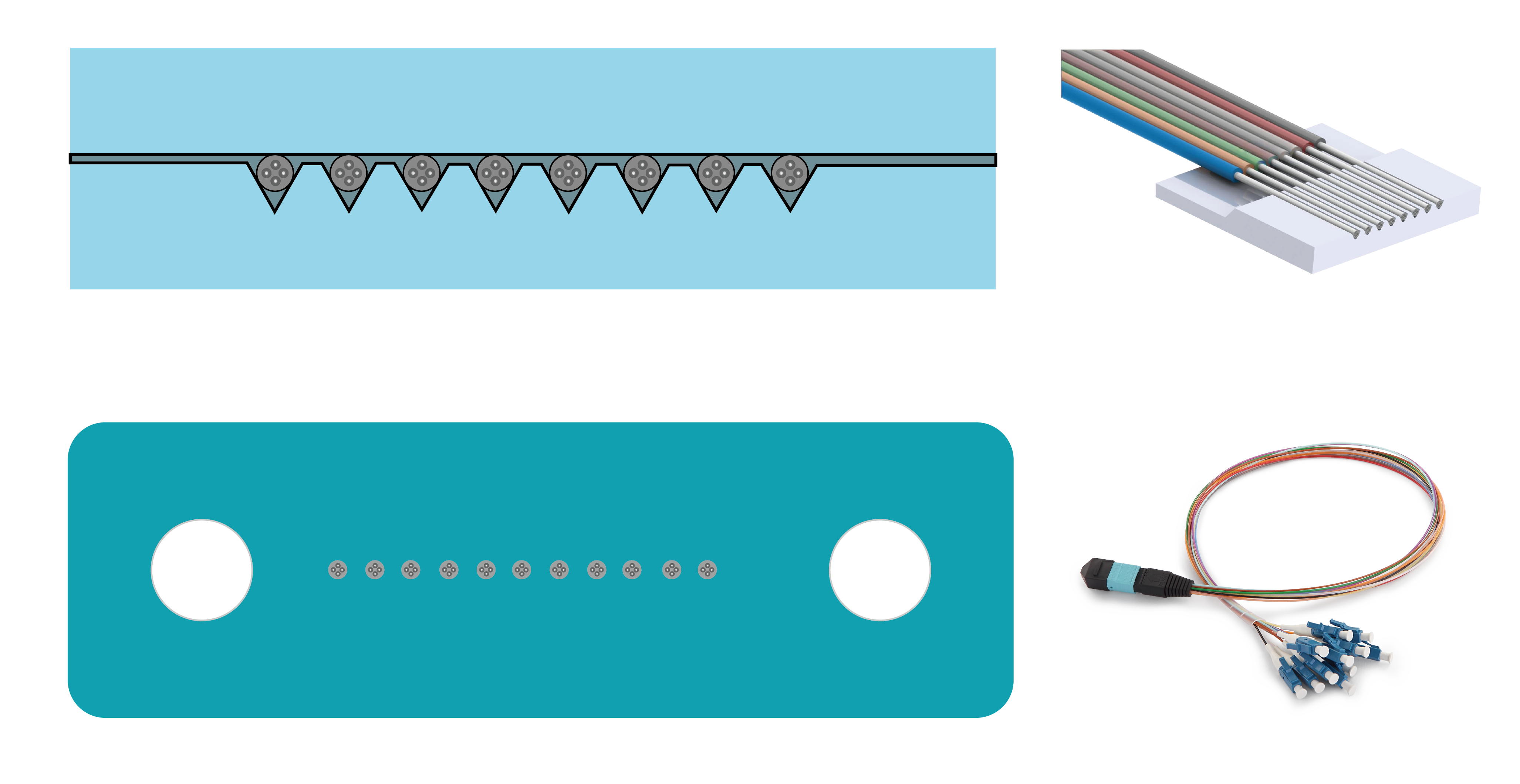

Multi-Core Fiber (MCF) takes a different route. Instead of changing the transmission medium, it increases the number of light-guiding paths within a single strand. Multiple independent cores are embedded within the same cladding, enabling parallel signal transmission that greatly enhances capacity without increasing the physical footprint of the cable.

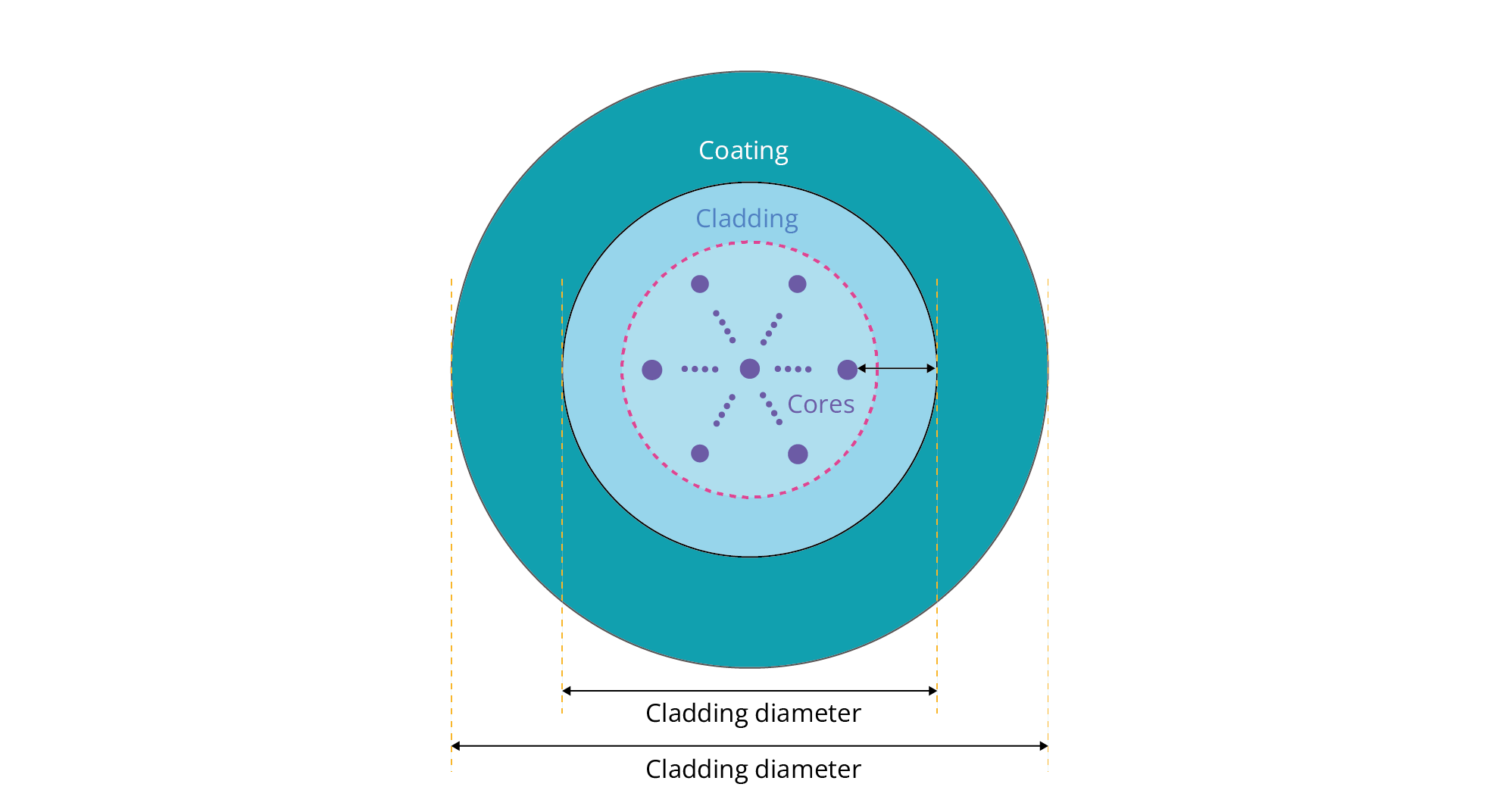

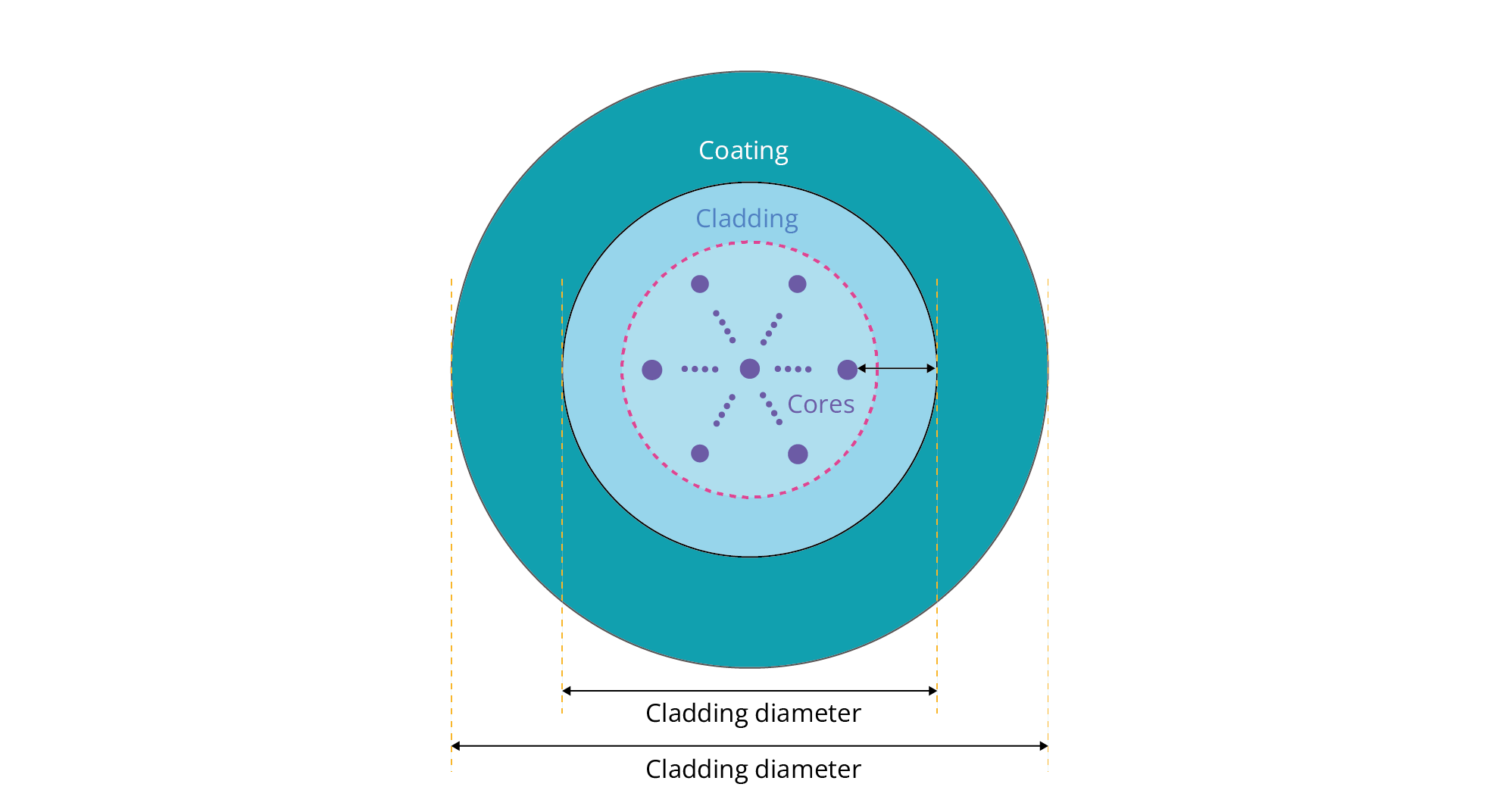

Beyond its transmission advantages, the versatility of MCF also lies in its structural design flexibility. As shown in the figure below, engineers can customize parameters such as the number and arrangement of cores, core geometry, outer cladding thickness, and coating diameter. These factors directly affect both optical and mechanical characteristics, so careful optimization is essential to achieve the desired balance for different applications.

This adaptability makes MCF especially appealing for data centers, submarine communication systems, and high-capacity metro networks—areas where physical space is constrained but bandwidth demands continue to grow. Although it requires precise splicing tools and currently lacks full standardization, MCF aligns well with existing manufacturing techniques, making it a more practical candidate for scalable network evolution.

Comparing Multi-Core and Hollow-Core Fiber

Feature | Multi-Core Fiber (MCF) | Hollow-Core Fiber (HCF) |

Transmission Medium | Solid glass with multiple light-guiding cores | Air-filled hollow core |

Capacity | Extremely high – multiple cores enable parallel data streams | Moderate – single core, but faster propagation |

Latency | Similar to standard fiber | Ultra-low – light travels through air |

Scalability | High – compatible with large-scale deployment | Low – best for specialized use |

Primary Use Cases | Data centers, submarine systems, high-capacity backbones | Financial trading, low-latency edge computing |

Main Challenges | Complex splicing, lack of global standards | High cost, low yield, limited compatibility |

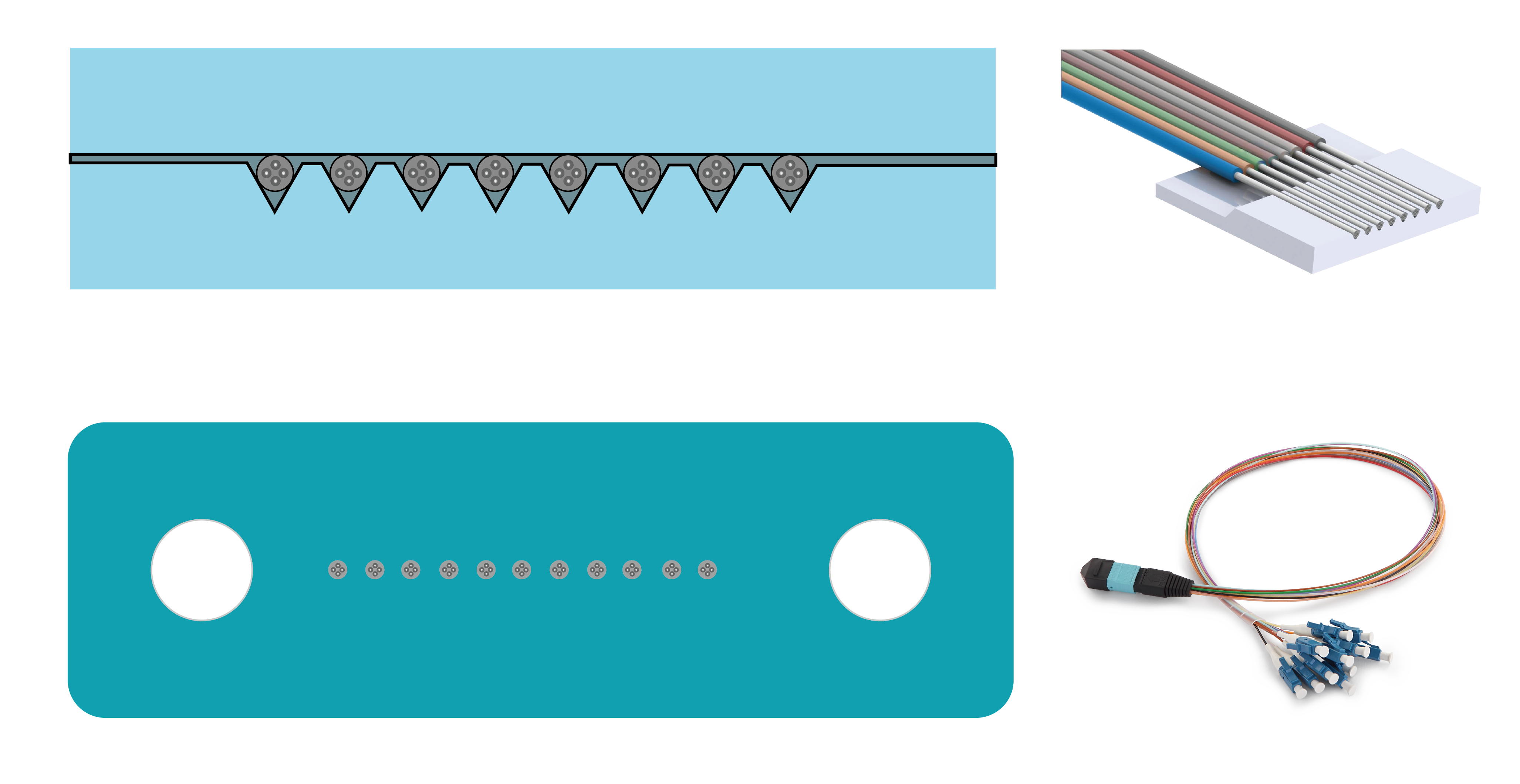

For decades, the optical industry has focused on miniaturization—developing thinner, lighter, and more sustainable cables. Slimmer designs reduce duct usage, lower material consumption, and minimize environmental impact during production and installation.

Today, the focus is shifting from “smaller” to “smarter.” Multi-Core Fiber represents the next logical phase of this evolution: instead of shrinking the cable further, it multiplies capacity within the same dimensions. This design philosophy allows operators to achieve far higher bandwidth density while maintaining established deployment and handling processes.

Why Multi-Core Fiber Is Gaining Momentum

The rise of Multi-Core Fiber is closely linked to the explosion of data traffic and AI-driven workloads. Modern data centers process enormous volumes of real-time data, from AI training and analytics to cloud computing tasks—all requiring greater bandwidth and lower latency.

While Hollow-Core Fiber remains unrivaled in pure transmission speed, its cost and scalability challenges limit broader adoption. MCF, by contrast, offers a balanced mix of performance, practicality, and forward compatibility. It can be installed in existing ducts, integrated into current optical components with moderate adjustments, and scaled to meet future growth.

Global research institutes and major fiber manufacturers are actively investing in MCF development, expecting it to play a key role in next-generation data center interconnects, long-haul networks, and high-density access systems.

At T&S, we are closely monitoring these developments and exploring ways to integrate MCF technology into our optical solutions. Although standardization remains a work in progress, it presents exciting opportunities for innovation and leadership in high-capacity connectivity.

Beyond Communication: Expanding MCF Applications

The potential of Multi-Core Fiber extends well beyond traditional communication networks. Multiple cores within a single strand can operate as parallel sensors, enabling simultaneous detection of parameters such as strain, temperature, and curvature with exceptional precision. This makes MCF highly attractive for applications in structural health monitoring, aerospace systems, and robotic surgery.

In industrial and laser systems, high-power MCFs can distribute energy efficiently across cores, improving safety and system performance. Similarly, in quantum communication, MCF’s ability to manage multiple photon states simultaneously positions it as a strong candidate for future quantum networking architectures.

The Influence of AI on Fiber Infrastructure

Artificial intelligence is now at the heart of the global digital ecosystem. Whether in autonomous vehicles, intelligent manufacturing, or generative computing, AI relies on high-speed, low-latency connections to process massive datasets. This accelerating demand for bandwidth underscores the need for fiber networks that can scale efficiently and cost-effectively.

Multi-Core Fiber offers a compelling solution. By dramatically increasing bandwidth density within the same cable footprint, it allows network operators to expand capacity without major infrastructure changes—a sustainable path forward for AI-era connectivity.

Conclusion

Hollow-Core and Multi-Core Fiber each mark important milestones in the evolution of optical communication—but their paths diverge. Hollow-Core Fiber will likely remain a specialized solution for ultra-low-latency use cases, while Multi-Core Fiber is emerging as the more practical and scalable foundation for the networks of the future.

By combining higher capacity, deployment flexibility, and compatibility with current infrastructure, MCF represents the natural progression of optical fiber technology.

At T&S, we are committed to advancing innovative connectivity solutions that make networks faster, smarter, and more sustainable. Although Multi-Core Fiber is still in the early stages of commercialization, its potential to redefine capacity and scalability is already reshaping how we envision tomorrow’s optical networks.

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm.

MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm. MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design.

MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design. EN

EN

jp

jp  fr

fr  es

es  it

it  ru

ru  pt

pt  ar

ar  el

el  nl

nl

_and_High-Reflection_(HR)_Optical_Coatings.webp)