T&S Traceable Fiber Patch Cords help eliminate interconnect errors in high-density environments. Designed for applications ranging from equipment backplanes to dense patch panels and cross-room connections, these cables feature a built-in light indicator for easy identification of the far end.

Each traceable patch cord includes an additional plastic fiber structure that enables quick and accurate cable tracing, even in congested routing areas. This makes them especially useful in environments where identifying cable endpoints can be challenging, such as inside-plant and outside-plant cabinets. Typical applications include data centers, central offices, mobile switching centers, telecommunications closets, fiber distribution hubs, and multi-dwelling units (MDUs).

TIA/EIA-568.3-D/ EIA/TIA-604 Series/ IEC-61754 Series/ IEC-61753-1/ GR 326 Core

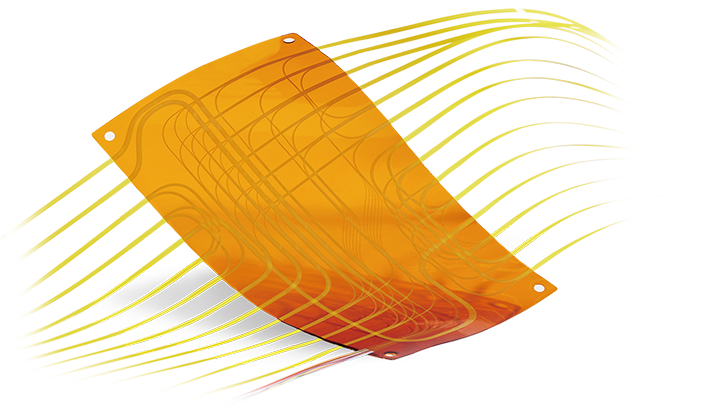

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing

Fiber Optic Flex Circuit (FOFC)

Advanced Simulation & Optimization, High Positioning Accuracy, Flexible Customization, Rigorous Reliability Testing MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm.

MDC Solution

US Conec's MDC connector is a Very Small Form Factor (VSFF) duplex optical connector, expertly designed for terminating single-mode and multimode fiber cables with diameters up to 2.0mm. MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design.

MMC Solution

US Conec's Very Small Form Factor (VSFF) multi-fiber optical connector that redefines high-density connectivity with its cutting-edge TMT ferrule technology and intuitive Direct-Conec™ push-pull boot design. EN

EN

jp

jp  fr

fr  es

es  it

it  ru

ru  pt

pt  ar

ar  el

el  nl

nl